Our offerings

Products

Get fast, detailed designs

General info & questions answered

Please add job name & number

Features and Benefits of CrystalStream Technologies Solutions Products

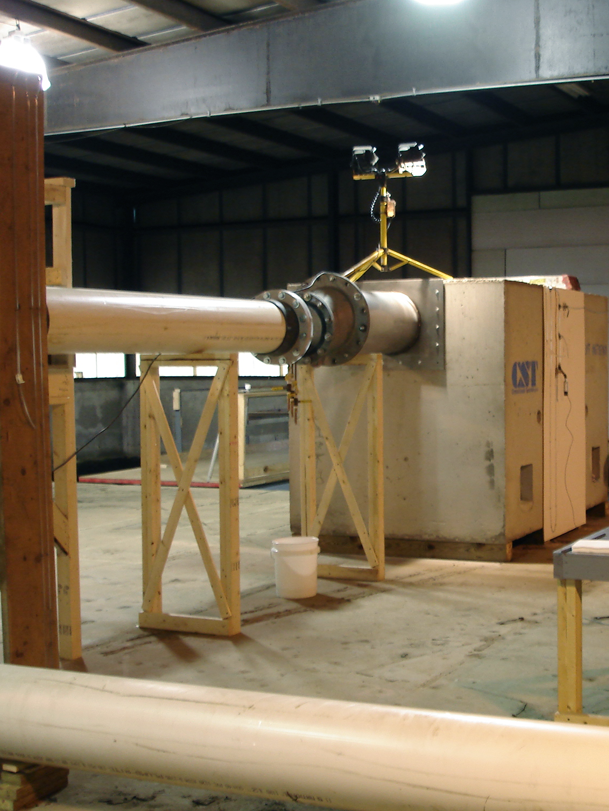

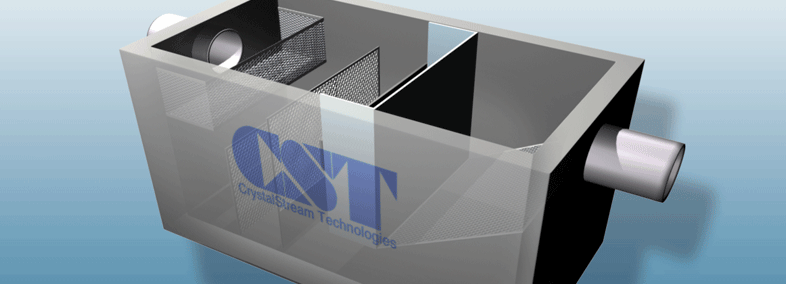

Our two primary product offerings serve to provide water quality treatment on almost every type of site with thousands of existing installations. The first device went in over 25 years ago and it still operating efficiently today. Our CrystalClean “separator” comes equipped with a fiber filter and is the product of choice for most sites. It has impressive total suspended solids removal but adds trash screening, nutrient screening and filtrations and generous spill protection capacity. Our CrystalClear-choice product works in a similar way to our separator/filter but adds a customized media box arrangement where all

sorts of media and filters can be selected based on the special needs of a particular site. Unlike most other filtration products, the CrystalClear device can be inspected, cleaned and maintained from ground level with no confined space entry required. The device can be adjusted to direct only certain reduced flows through the media boxes while all flows get the normal CrystalStream trash, nutrients and total suspended solids treatment. Which product is right for your site? Please fill out our Design Form or Contact Form and let’s start a conversation about your individual site needs.

Primary Features

• Trash basket targets nutrients

• Fiber filter catcher organics and metals

• Baffles distribute flow to maximize separation

• Spill protection built into every device

Download the

CrystalClean-Separator.pdf

CrystalClean (with Filter) Separator

Resume – 25 Years of Steady Employment

This is our original product and the most popular. Outstanding test results in the field have shown this product to be capable of stand-alone water quality treatment on many sites and in most jurisdictions. Please check out our field test results in our downloads section. For each test, the agency purchased a commercially available, stock device and then tested the device at their expense, analyzed the results, and published their own report without our participation or using any of our funds. These were true, third-party tests. The results speak for themselves.

Reliable Results. Every Time.

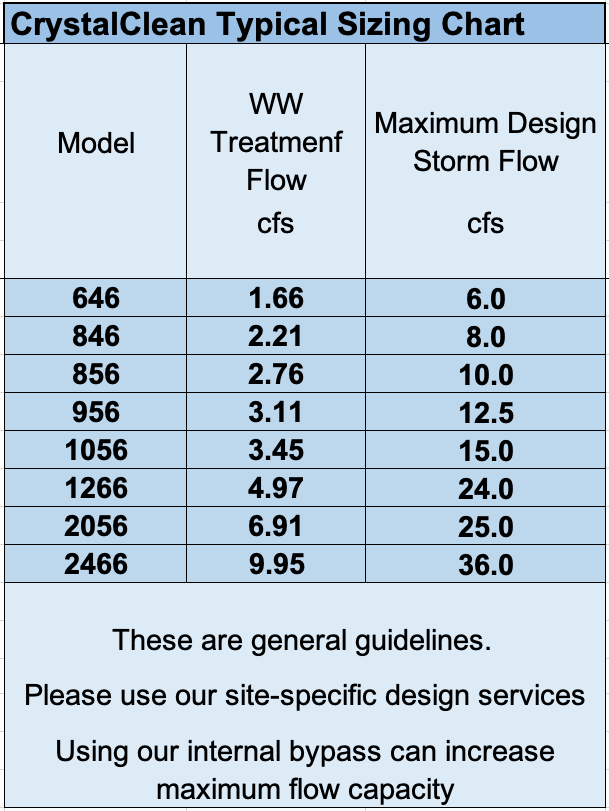

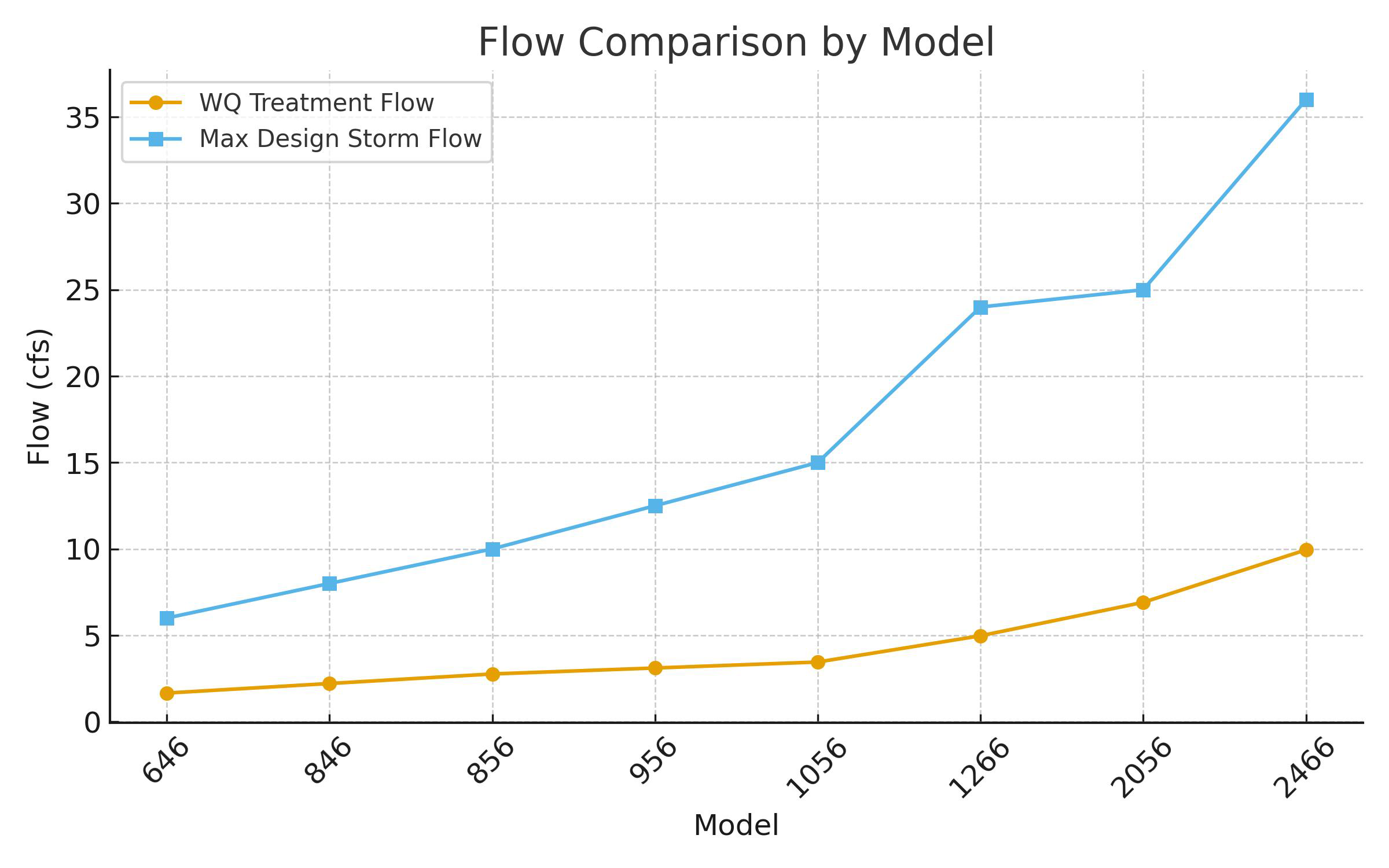

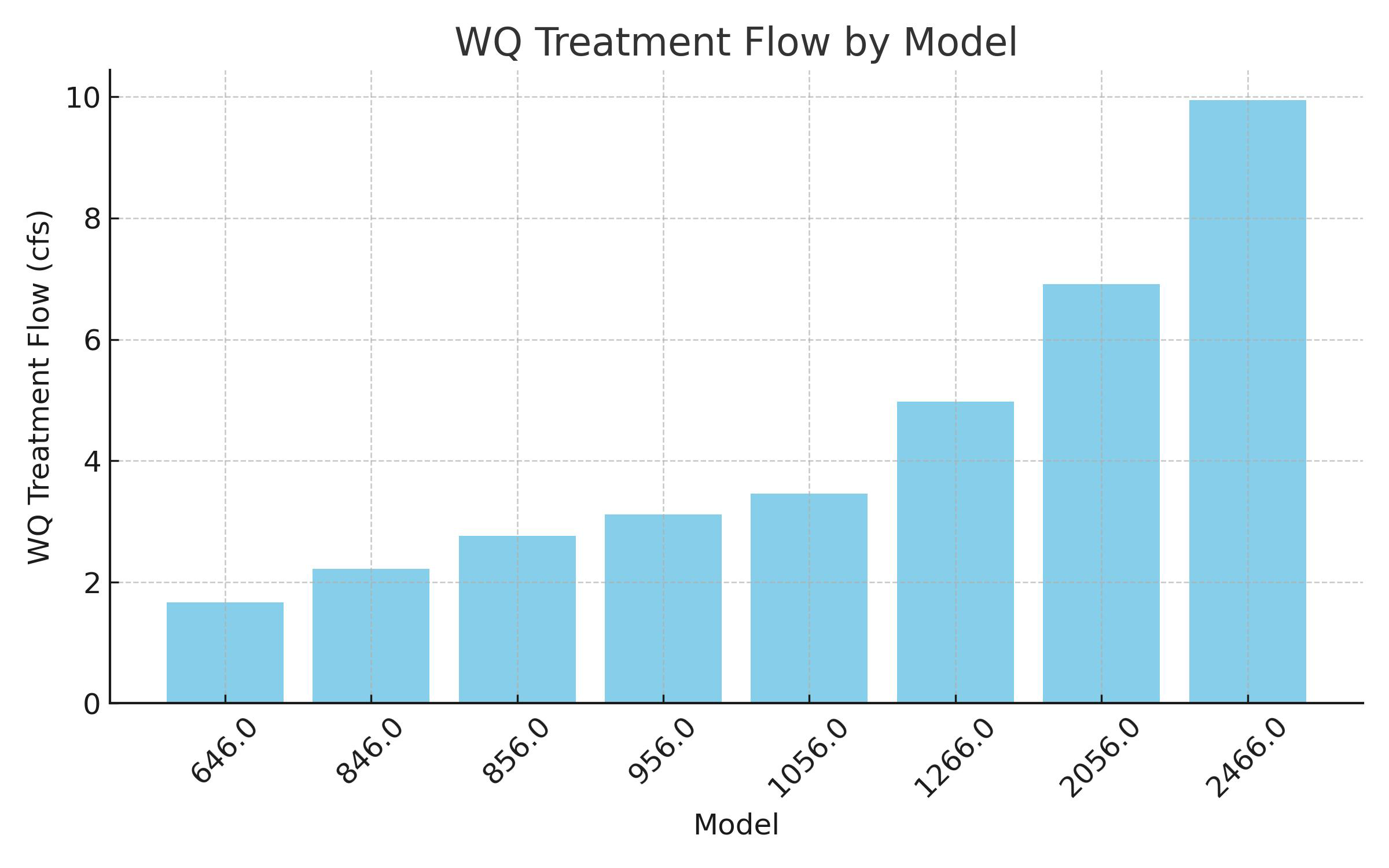

For critical sites or jurisdictions with highly restrictive requirements, this machine is an effective pre-treatment or full treatment system that controls trash, debris, accidental spills, and will remove 89% of all solids that reach the device. From high density hot spots to pre-treatment for sensitive land-based LID applications, this is the machine of choice. The CrystalClean separator can treat water quality flows from 0.4 to 9.95 cfs and typically remain on-line for maximum flows of 2 to 36 cfs over the range of models.

Versitle and Adaptable

We can help engineers design arrays and diversions for many more possibilities if the flows on your site are above 36 cfs. We support right or left side entry and exit configurations which makes our device perfect for tight spaces and complex layouts. Whether you know what you need or are unsure of the proper CrystalClean model to use, please click the Design Form button to let us get started on your site-specific design.

Typical Sizing Chart

This chart can give you a general idea of the CrystalClean model you may need, but please let our staff help you determine the correct device for your needs by filling out our design form. There is never a charge for our design work or consultation, and often we can help you save time and money by taking the time to look at your overall drainage design.

Beyond the Detail Drawing and Design Report

When your design is complete and you have received the detail drawing and design report to accompany your plans, you should know that there are more documents that support that site specific design. We put a detailed concrete fabrication document and an internal parts specification in your site file that matches the device detail and specifications we sent you to use in your plans. These “background” details are worked out in advance to be sure that the device is ready to build and deliver to your site location with no further modifications, and that our suppliers can perform the work precisely to our specifications. These details allow our suppliers to give you a fast and accurate quote when the time comes to order the device and have it delivered in a timely manner.

Support When You Need It Most – Revisions

We understand the process from initial planning, through submission to the jurisdiction and on to permitting. Changes to your plans happen often up until the permit is issued, and construction issues may even force changes after permitting due to unforeseen circumstances. We keep all your plans on file along with our design calculations so that we can make revisions quickly and accurately right up until the time that the concrete vault is poured. We usually turn around revisions within two business days. The revision work is not limited to the detail drawing. Because we have all the concrete fabrication and internal parts documents on file, we can make the necessary changes and supply new documents to the precaster and metals shop in short order. This assures that the device matches the revised drainage plan and will arrive in good shape, fully assembled and ready to install by the contractor.

Primary Features

•Your choice of meda

• Infinite combinations of treatment

• Easiest and least expensive inspection and replacement of media

• When new media is invented, we can install it.

Download the

CrystalClear-Choice .pdf

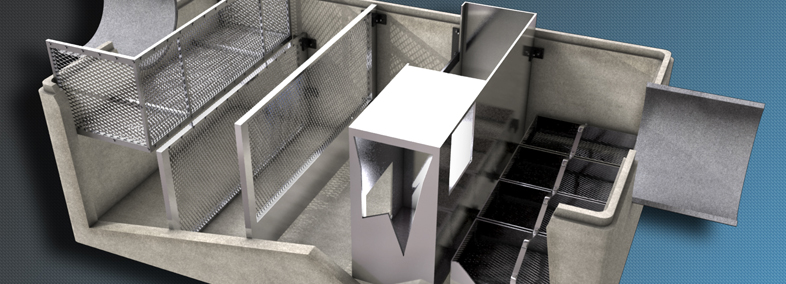

CrystalClear-Choice

This New Product is the Result of Our Latest U.S. Patent

Imagine our highly successful CrystalClean separator with the added ability to add the filtration material and media treatment elements of your choice. This breakthrough allows us to put the proven separation treatment elements on the front end of a device while sending a controlled initial flow of contaminated water into an up flow treatment system that provides targeted elements to remove specific pollutants. The concept is to separate trash, debris, hydrocarbons, sediment and other gross pollutants initially, and then to send that much cleaner water to a separate chamber for additional treatment. There is no chart here that shows flow capability because every device will be different. The CrystalClear-Choice will always have two sections separated by our “periscope” bypass structure. Sometimes both sections can be built into one precast concrete vault but often there will be two or more vaults required.

Divide and Conquer

The front separator system will be designed to remove 90% of suspended sediments down to a specific size along with the larger trash and debris. After separation, the periscope bypass structure will direct most of the flow up and out of the system, while the periscope will permit a measured amount of flow to pass under the bypass structure where it will rise up and out through the media boxes in the second chamber. The media will be chosen based on the targeted pollutants of concern. The thickness of the media, the resistance to flow and the contact time needed to treat the water all will be figured into the size and number of media boxes required for the device to operate successfully.

Opening a New World of Specialized Sites

There are many applications for this type of device in stormwater treatment, but also outside of normal stormwater treatment. The device can certainly be designed to target some specific pollutants that defy treatment by a separator, but it also can serve industrial sites where it is difficult to prevent stormwater from entering some processing areas and specific constituents can find entry into certain stormwater drainage systems. Please use our Design Form or Contact Form to let us get started on your CrystalClear-Choice design process.

Inspection in the Sunshine. Replace Only What Is Needed and Keep the Rest

The media boxes in the rear chamber can be lifted out for inspection. If there are several types of filters or media bags, each can be inspected and only the ones that are exhausted or spent will be replaced. This is not done in a dark chamber underground, but out in the open in daylight. Consider a bottom lining of coconut fiber or non-woven material designed to protect the more senditive media further up in the media box. Above that protection, there might be a bag of perlite, followed by a bag zeolite. The bottom protection might be partly occluded and ready for replacement and the perlite might also be exhausted. They might be replaced while the protected zeolite looks good and is still effective. With several media boxes in a grid, some of them may be more impacted than others. No matter what, this is all done in a safe and open environment.

Macro Treatment vs. Micro Treatment. The Choice Is Yours.

You might say separation versus filtration but the “Choice” offers more options than those two. The front section pays attention to “macro” pollutants and screens things from plastic water bottles to grass clippings and small trash. The front also lets sediments and anything else that can settle out of the stormwater collect in that section. This is important for two reasons. The front section is designed to be cleaned by conventional means and it stops the “macro” materials from impacting the filters and media in the back section of the device. In between the two sections is a “periscope” bypass that can be set to only allow a portion of the water flow to pass under the bypass and go up through the media boxes. Any flow above the bypass level will go up and through the periscope bypass without impacting the media boxes as it goes up and over them to be discharged. The possibilities are practically endless. Send us a design form or make contact so we can take a look at your site’s special needs.

CrystalStream Products Are Built in the USA,

with USA-Produced Source Materials

They are made of concrete, sheet aluminum, perforated aluminum, expanded aluminum and aluminum angle. These materials are available and we buy them in the USA. This is absolutely not true of our competitors. Since the pressure to get a site reviewed, permitted and constructed is often paramount during the initial phase, it is tempting to overlook the long-term needs of the eventual site owner. When an engineer chooses to specify a particular product, it is important to consider cleaning, maintenance and parts replacement in

the long term. We have devices that have been in the field over 25 years treating stormwater successfully, and eventually things can wear out or be damaged by misuse or neglect. Every single part in our devices is easily fabricated by any competent metal fabrication shop. We keep the metal fabrication documents on file for every device made in the last 20 years, so when a couple of tons of concrete is dumped into your device by a rouge truck driver, we can get your device back into service as good as new.

If You Are a Quality Precaster, Let’s Talk!