About CST

About

Founder John Moll and His Team

Have Directed CST from the Beginning

The vision has not changed. The main goal is cleaning up watersheds. There is no removal rate until material is removed from a structural treatment device so make it serviceable. Target more than just sand and sediment. Stay online if possible. Make every part from common materials and replaceable. Every site is unique, so make every device site specific. Our devices work because we design them to work. We are competitive with any structure that can deliver our results. Our field testing supports our claims. We are proud of our results. See how we can benefit your site and reach out to us today.

Welcome to CST

CST Founder John Moll with his 9th patent, issued by the United States Patent Office, recognizing CST’s ongoing technological developments for water treatment.

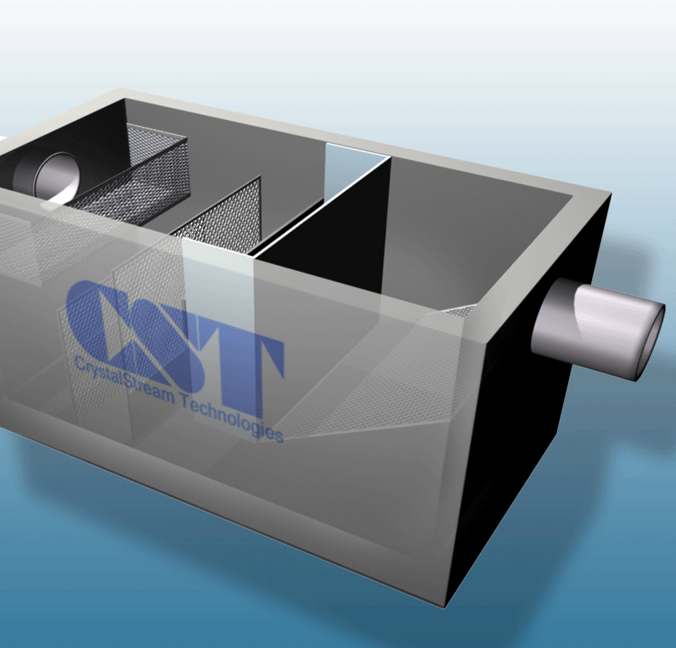

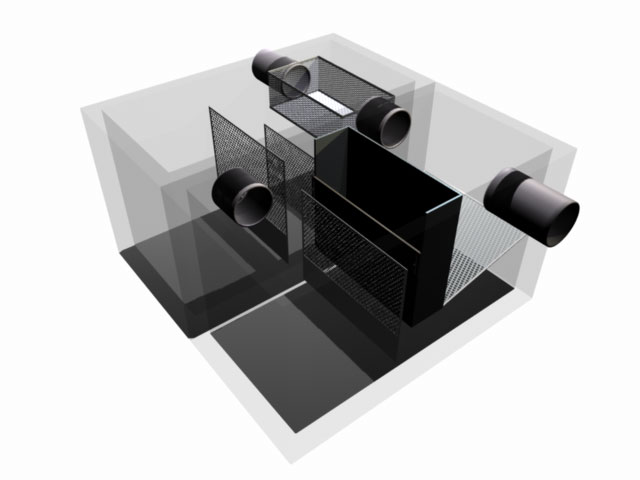

This combination of screening, separation, flow control and filtration has stood the test of time for 25 years and continues to improve watersheds.

Stormwater Treatment

Practical Best Management of Georgia, Inc. holds the patents to the CrystalStream™ Technologies family of stormwater treatment BMP products and determines the business plan and mission for each geographical area served. That plan requires that we maintain control of the engineering and design for every stormwater treatment BMP device that bears the CrystalStream name. We concentrate on the business at hand, which is providing the right CrystalStream device for each water quality application.

Our job is to consult with municipal officials, engineers, contractors, and end users to be sure that we take all the steps necessary to place the correct device on each site. We don’t rely on a chart where pre-designed units are listed that you can by flow volume from to order from our suppliers. Our engineers will interface with local officials and your local design professional to find out what size and type of unit to propose. We will then provide design reports and detailed drawings.

Two different sites could have the same run-off flows but could also have very different pollutants washing off and will need specific design elements to deliver proper stormwater treatment.

“One size fits all” for water quality treatment is not a good idea and is not our policy. Once a design is approved and permitted, our people will work with the contractor to be sure that ordering, delivery, installation, and all follow-up goes smoothly. After installation, they will work with the site owner to establish a working relationship for ongoing operation and maintenance of our device. Does this sound different from other BMP manufacturers? With CrystalStreamTM Technologies, you don’t just get our device, you get results!

Design, Installation, and Maintenance

The Three Components for Success: Design, Installation, and Maintenance: each of these elements is essential to success with a BMP. Together they make up our business plan.

DESIGN

INSTALLATION

MAINTENANCE

Design

We know that “one size fits all” does not work for stormwater treatment. All one-acre sites are not the same. Based on the amount of impervious surface coverage and local climate, the flows will be different. Depending on the pipe system design characteristics, the velocities will be different. Every credible BMP design relies on flow and velocity, but there is much more to consider. What are the pollutants that are likely to wash off this one-acre site based on the proposed usage? What are the characteristics of the watershed? These basic principles, along with differing local regulations, show that we must design on a site-by-site basis. We do not have a list of “one size fits all” models.

Installation

We know most people do not routinely install structural stormwater treatment devices, so they do not have the knowledge or equipment to assemble and install these products.

Our products come fully assembled, functional, and ready to “grout in”. This will help ensure a stormwater treatment device will work as designed because it will be properly installed.

You will not find instructions like “Contractor to adjust based on field conditions” or “Not to Scale” on our details. You will find our “800” number clearly displayed so that you can call us to help answer your questions prior to and during installation.

Maintenence

We stay with our site owners after the sale. We can help them find economical cleaning and maintenance and provide an operations and maintenance manual for their use.

Every customer can call our affiliate, Storm System Services at 678-990-0178 for any problem that may occur, from a fuel spill in his parking lot to a routine city inspection. They offer service many areas but will also help find qualified maintenance companies. Find Storm System Services at stormsystemservices.com.

Achieving good water quality is not a product – it is a process!

Moving to Green. Keeping It Green.

CrystalStream field testing has shown that our devices remove nearly 90% of suspended solids from stormwater runoff, but even the lowest rated devices with only laboratory testing have been shown to remove 50% of suspended solids. The large size of green infrastructure (in comparison to manufactured vaults) indicates that they are capable of removing even more solids. There is more involved than simply size, but the reality is that the field performance of ponds, infiltration structures, bio-swales and similar “green” infrastructure is that they fail to perform up to their potential. This is mostly due to the impact of excess trash, organic debris, and large sized sediments that can easily be trapped and removed in a manufactured water quality device such as ours. It is much easier and less costly to clean out a concrete vault than a wet pond or constructed wetland. A device that catches 90% of the material contained in stormwater will extend the life of an efficient “green” structure by a factor of ten. That would stretch a two-year life to twenty years. Even a 50% efficient device would double the life of a large land-based structure.

Undercover/Underground Operations

Underground detention, retention and infiltration are extremely popular in today’s market for several reasons. Typically, the structures go under parking lots or other surface uses so that valuable real estate can be saved. Even though these installations are typically impossible to effectively clean and lack safe entry points for maintenance, they are somehow given “credit” for removing pollutants from stormwater. This is difficult to understand when nothing is actually removed from the structure. Jurisdictions have realized this shortcoming and are now demanding that these structures be inspected and cleaned on a regular basis. This is difficult with there are very few inspection or entry points, if any. As stated above, a device that catches 90% of the material contained in stormwater will extend the life of an underground structure by a factor of ten.

It is becoming good practice to install a manufactured device upstream of these structures to reduce the amount of material that enters the underground chambers. A device that bypasses at relatively low flows will allow all trash, debris, hydrocarbons and other floating materials to wash over their bypass weir and become trapped in the hard to clean underground structure. Our CrystalStream products are ideally suited to be installed upstream of these popular structures to extend their life and reduce their cleaning cost by a factor of ten. This practice will pay for itself in short order.

Brief History of Water Quality

The history of stormwater regulations begins in 1972 with the passage of the Clean Water Act. Initially, the CWA prevented the discharge of pollutants to any navigable waters from a specific source unless it was authorized by a permit from NPDES, the National Pollution Discharge Elimination System. That system generally exempted most stormwater run-off that was not associated with a single entity. In 1987 the Water Quality Act was passed that included a wide variety of sources and separated the permitting into municipal and industrial sources. The Phase 1 rules included “non-point” sources of pollution for municipal separate stormwater sewer systems or MS4s. This was the impetus for best management practices (BMPs) to be utilized on individual sites to reduce the pollutants that were discharged from those individual sites. In the years since, permits have been revised and other general categories such as Phase II permits have been implemented. CrystalStream Technologies came on the scene in late 1999 with our first devices being placed in the field in early 2000.

We started placing devices on sites to help engineers comply with local, state and federal regulations at that point and have since placed thousands of devices in the field. We applied for patents on our innovative designs and have been awarded nine U.S patents for various features incorporated into our vaults. In 2005, we were field tested under the EPA’s Environments Technology Verification program (ETV) in Griffin GA and later were field tested by the USGS on a South Carolina DOT site. Our final field test was conducted under a grant to the Clean Water Management Test Fund in Highlands, NC. In each of these field tests, the agency bought one of our devices, locked it down and took samples to measure performance. The sampling was conducted and paid for by the agencies involved and the samples were analyzed in certified laboratories. Then, the agencies independently published the results for all to see in reports that they compiled and made public. Today, we continue to place devices into the field to help meet water quality standards based on our testing and long term field success.

"Clean Water is a basic human right. Without it, the other rights may not even matter. Human societies cannot be healthy, prosperous and just without adequate supplies of clean water. "

— President Jimmy Carter

Get fast, detailed designs

General info & questions answered

Please add job name & number

If You Are a Quality Precaster, Let’s Talk!